The landscape of industrial applications is changing quickly, especially in the realm of universal testing machines. Advancements in technology are making these machines more precise and efficient than ever, transforming how materials are tested across various sectors.

As industries continue to seek higher standards of quality and safety, the integration of automation and smart features into testing equipment will play a crucial role in meeting these demands.

I find it exciting to see how artificial intelligence and robotics are being combined with traditional testing methods. This shift not only streamlines testing processes but also enhances data accuracy, allowing for better compliance with global standards.

Keeping up with these changes can seem daunting, but understanding these trends will empower us to adapt and thrive in this evolving field.

Exploring these future trends in universal testing machines will give us a peek into the advanced capabilities that lie ahead. From improved data collection to automated systems, these developments promise to reshape the way we understand and analyze material properties in our industries.

Advancements in Material Testing

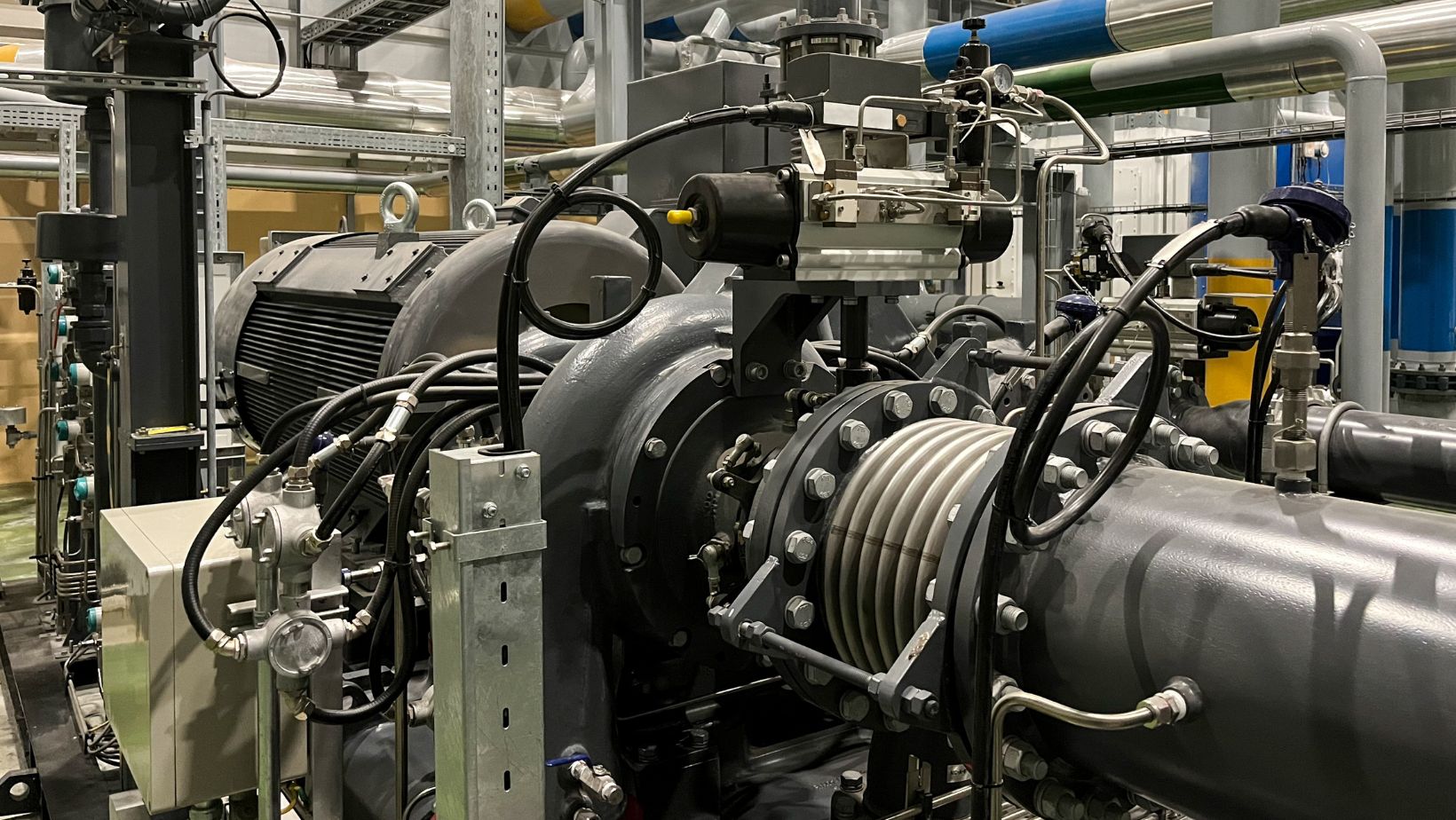

There are exciting changes happening in material testing. Recent innovations focus on load frame design and control systems, which are both important for improving testing processes.

Innovations in Load Frame Design

New load frame designs are making testing more efficient and effective. These frames use advanced materials that reduce weight while maintaining strength. With a lighter frame, I can easily move and set up machines, which saves time.

Engineers are also incorporating modular designs. This flexibility allows for quick adjustments based on the specific material being tested. Moreover, improved load cell technology gives more accurate data. A table below summarizes key benefits:

|

Benefits |

Details |

|

Weight Reduction |

Easier to handle and transport |

|

Modular Design |

Customizable for different materials |

|

Enhanced Accuracy |

Better load cell technology improves results |

With these advancements, testing can become faster and more precise.

Progress in Control Systems and Software

Control systems are becoming smarter with software upgrades in NL Test. These systems enable real-time monitoring of tests. I can track data instantly and make decisions based on results as they happen.

Additionally, advanced algorithms help predict material behavior under stress. This predictive capability leads to safer designs and better performance. Features like intuitive user interfaces make operation simple and user-friendly.

Integration and Automation in Testing

As testing technology advances, integration and automation play a crucial role in enhancing efficiency. By focusing on better data acquisition methods and incorporating robotics and AI, testing processes can become more streamlined and accurate.

Enhanced Data Acquisition and Analysis

The evolution of data acquisition systems has significantly improved the quality of testing. Modern Universal Testing Machines (UTMs) now feature advanced data collection methods. For instance, some machines use 24-bit ADC resolution and can sample data at rates up to 1000 Hz.

This level of precision allows for detailed monitoring of material behavior under various conditions. The information gathered can be analyzed to identify patterns and insights, helping in making informed decisions. This capability is vital for research and development, where accurate data can lead to innovation.

With enhanced data analysis, companies can reduce errors and improve product quality. This helps them to meet industry standards more effectively.

Robotics and Artificial Intelligence

Robotics and AI are transforming how testing is performed in industrial applications. By integrating these technologies, I can automate repetitive tasks, making the process faster and more reliable.

AI can analyze data from testing machines to optimize procedures. For example, it can detect anomalies during tests and provide immediate feedback. Meanwhile, robotics can handle physical tasks with precision, reducing human error.

This combination leads to smarter testing environments. It allows for real-time adjustments based on data, improving efficiency and accuracy. As I use these technologies, I can ensure better results while freeing up time for more complex analysis.